Capabilities in

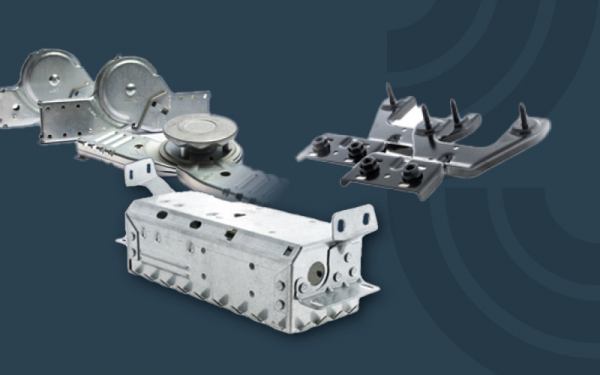

Stamped and Formed Parts

SteelCo.Tech to position itself as a trusted partner across a range of industries, including automotive, medical technology, environmental technology, solar, and photovoltaics. The company's strength lies in its ability to manufacture high-precision stamped and formed parts tailored to the demanding requirements of modern industrial applications.

At the heart of SteelCo.Tech’s manufacturing expertise is the use of complex progressive and transfer tools. These enable the production of sophisticated stamped, drawn, and bent components that meet the highest quality standards. Whether it's large-scale production or small batch manufacturing, the company’s extensive machinery – comprising state-of-the-art servo presses, versatile hydraulic presses, and both toggle and eccentric presses – ensures flexibility and precision across all production volumes. For small series, dedicated insert presses are employed to maintain cost-efficiency without compromising on quality.

In addition to its advanced tooling and machinery, SteelCo.Tech places a strong emphasis on process-integrated automation. This includes everything from in-line stamping and thread moulding to the automated feeding of screws, nuts, sleeves, and bearing elements. These fully integrated processes not only enhance production speed and consistency but also offer customers a significant competitive edge through reduced lead times and increased reliability.

With a clear focus on innovation and quality, SteelCo.Tech is setting new standards in metal processing – delivering high-performance solutions tailored to the evolving needs of its customers worldwide.